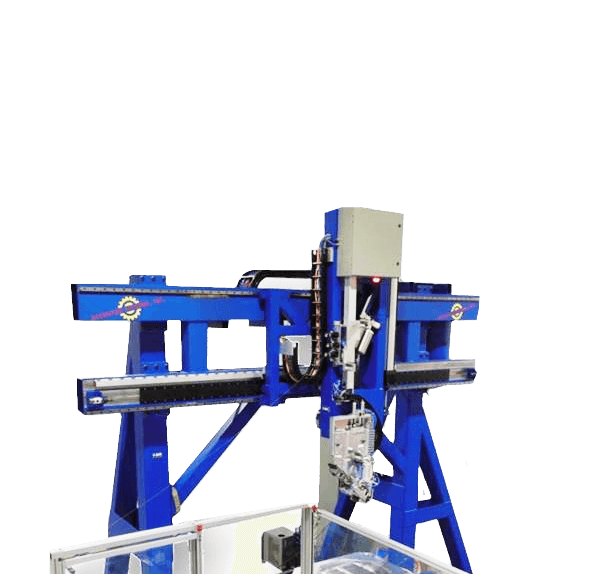

Accudyne had been commissioned to develop the 4th generation of a multiple module, automated manufacturing system for a global aerospace company.

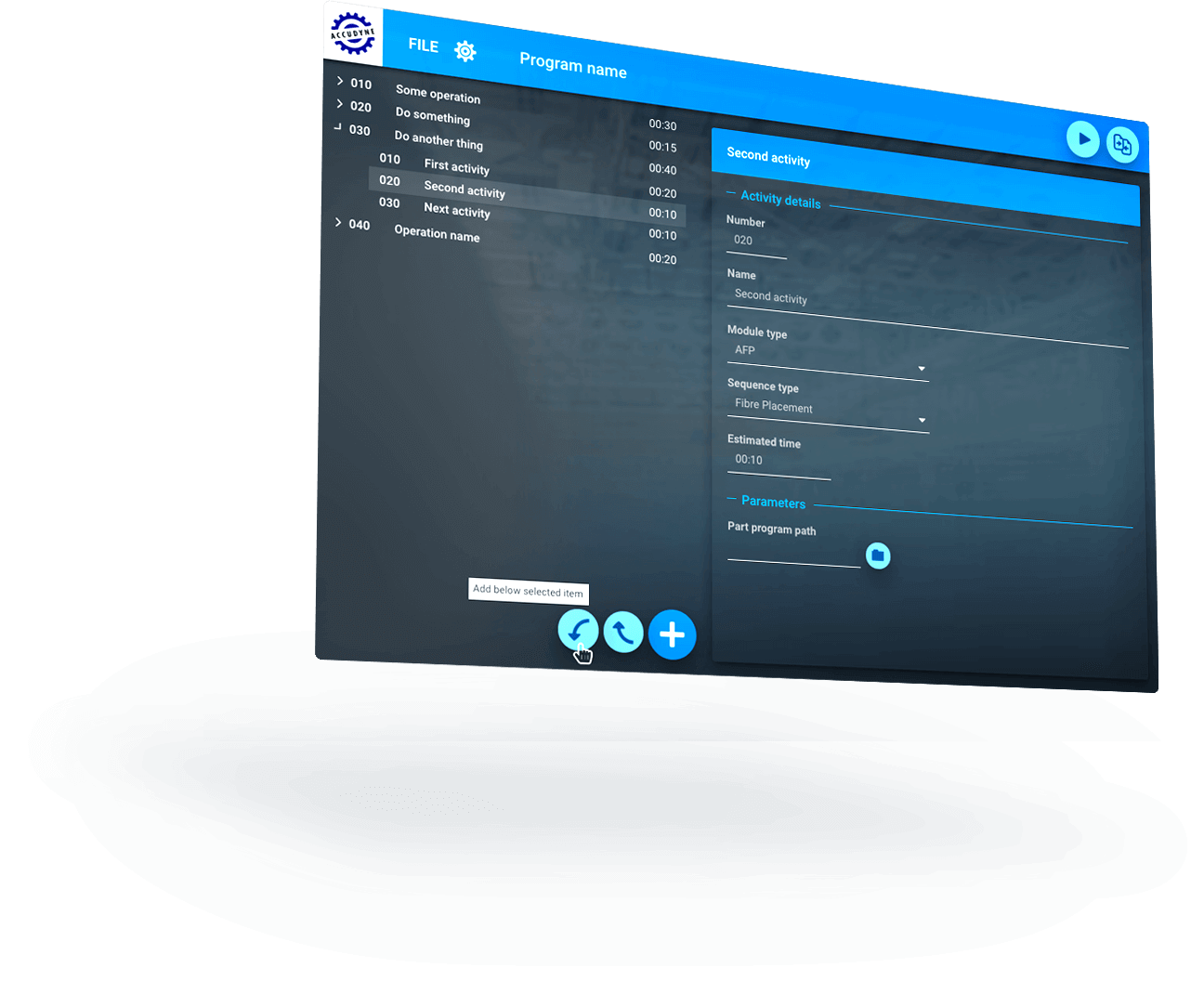

With such a large project and tight timescales Accudyne chose to outsource the development of a software tool to manage the programming and configuration of the manufacturing modules. With the manufacturing modules controlled by XML programs that set out the detail of the ordering of operations and activities, the tool enables them to simplify the task of updating module programs, to reduce errors and manage change control.

With Accudyne having agreed a detailed requirements specification and specific standards for the development with their customer, First Option had to ensure all aspects of the software were developed to a high level of finish.